Dentalight started in 1997 as a family owned handpiece repair shop that served local dentists. We soon realized that there was an opportunity to provide services that were not available to independent repair shops. We phased out our retail business with dentists and began providing fiber optic replacement and other specialized services to handpiece repair shops. Since then, we have replaced more than 28,000 fiber optic bundles and rods in dental handpieces, LED lighting systems, and many other repairs.

All work is done in our facility. This gives us complete control over the quality of materials, workmanship, and turn-around time for your customers' instruments. Materials used are the best that can be sourced, regardless of price. All products are rated for autoclaving, and many exceed factory standards. For most repairs, we provide a six month warranty on materials and workmanship.

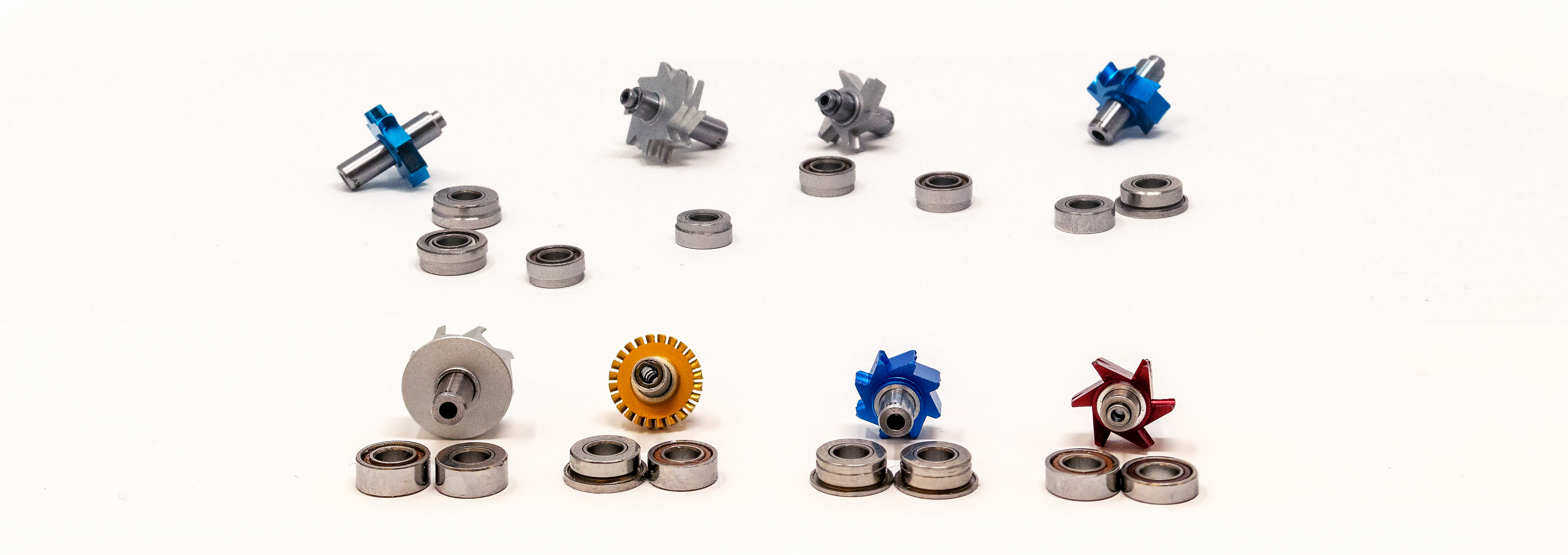

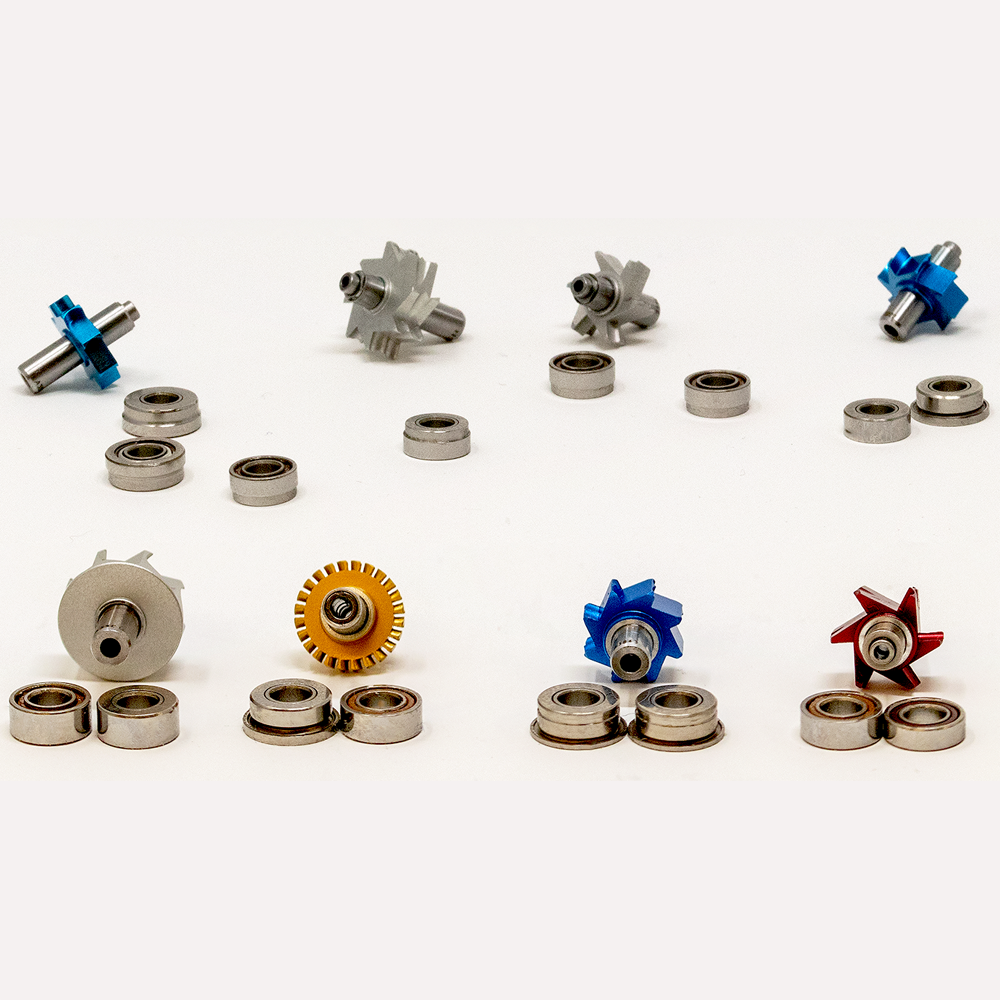

We have developed long term relationships with manufacturers of highspeed spindles, impellers and bearings. These sources are ISO compliant and have a solid history of providing quality products. Because our relationships with our primary vendors have lasted over 20 years, we are able to bring to market products and services that are available exclusively from Dentalight at a competitive cost.

Syntek full synthetic lubricants, available in aerosol and dropper, are proudly made in America. Drill Juice is our chuck cleaner, which is unique in the industry. These are brands that Dentalight owns. Syntek was specifically formulated for use in all dental instruments and is more competitively priced than foreign brands.

Syntek is a 100% full synthetic lubricating oil, made in the USA, specifically for use in dental instruments.

Most lubricants offered in the dental industry, including most major brands, are derived from a mineral oil base, which is inferior to Syntek in every measurable way. If your present lubricant is synthetic, it will be noted on the container.

Syntek is superior to mineral oil in the following ways:

- Syntek provides higher film strength than mineral oil. This means less wear, more torque, and higher instrument RPMs.

- Syntek is unaffected by autoclaving. It will not break down, cause varnish buildup, or gel the way mineral oil will. It will not absorb water. Mineral oil absorbs water and thickens during autoclaving, resulting in lower torque and diminished protection.

- Syntek has passed all protocols, including wear, free running rpm, and sterilization by a leading bearing manufacturer. It is certified “Food Grade” and is safe for use in all dental applications.

- Syntek is an easy-to-use one-step product. It is applied before sterilization to both clean and lubricate. There is no need to lubricate after sterilization! Instruments become contaminated when they are lubricated after sterilization.

- Syntek is formulated for use in all dental instruments, including high speeds, slow speeds, electrics, hygiene handpieces, all attachments, and nosecones.